PRODUCT

CONTACT US

Pangu Tiandi, Economic and Technological Development Zone, Linyi City, Shandong Province

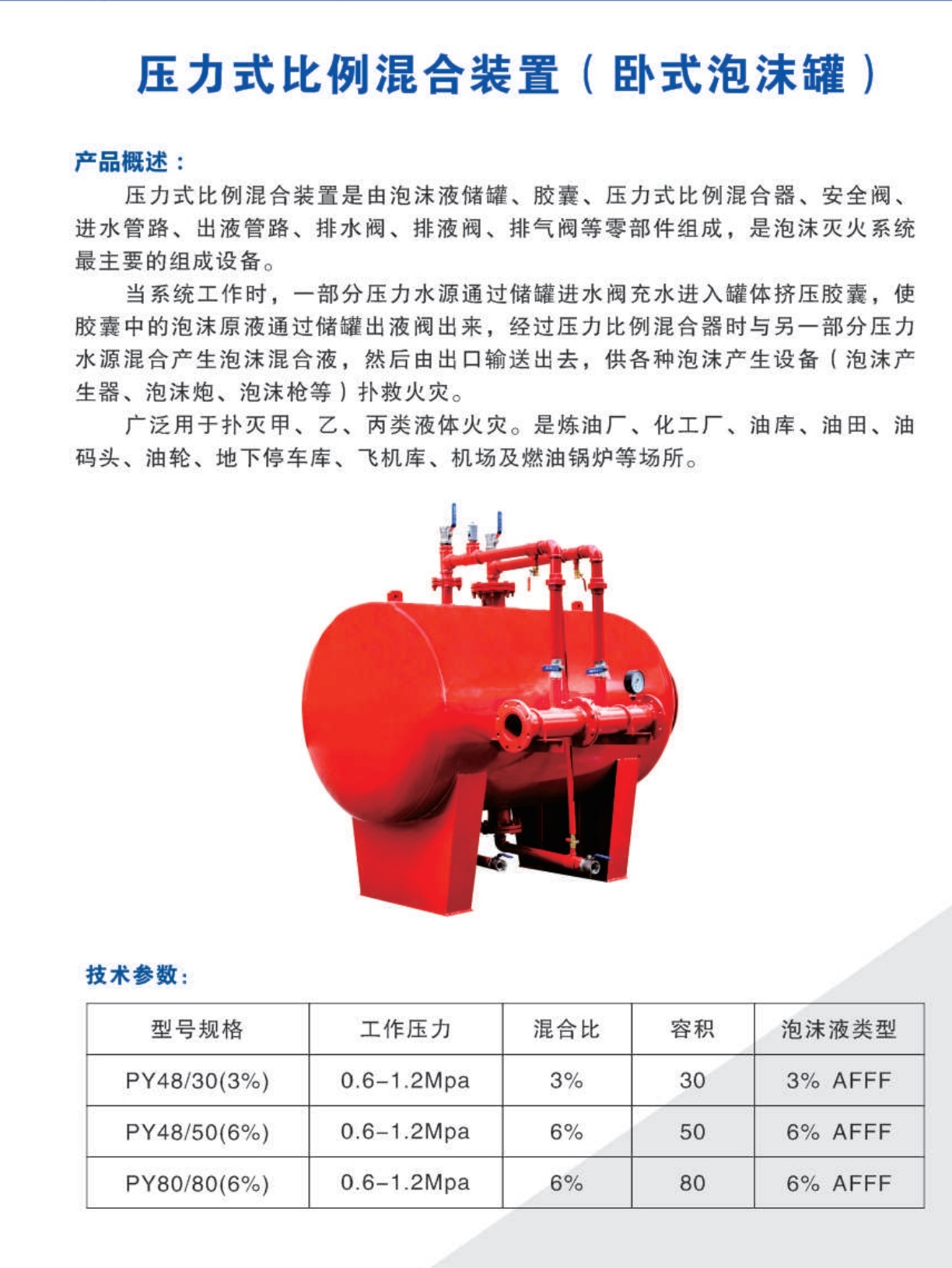

Product Description

Working principle

Flame detector An elliptical optical window is installed on the panel, and high-purity quartz glass is used as the window material. Thanks to quartz glass’s excellent transmission capability in the ultraviolet wavelength range, it meets the requirements for flame detection. At the same time, its high strength and hardness ensure compliance with explosion-proof and flameproof specifications. Sensor A cold-cathode ultraviolet phototube is used to convert flame combustion parameters into electrical pulse signals. These signals are then fed into an industrial computing chip for computation and processing, enabling timely detection of the burning flame.

When the control system receives an alarm signal from the flame detector, it promptly activates the extinguishing device and the audible and visual alarm system, drawing the attention of personnel on site.

Product Introduction to Flame Detectors

1. Flame detector It can be applied in locations where flame monitoring is required, enabling rapid detection of burning flames that could potentially cause fires and timely issuance of fire alarms. ;

2. Flame detector A cold-cathode ultraviolet phototube is used to convert flame combustion parameters into electrical pulse signals, which are then fed into an industrial computing chip for computation and processing, in conjunction with... Control system can promptly issue a fire alarm. And extinguish the source of fire;

3. Flame detector housing It features an aluminum die-cast explosion-proof enclosure with excellent explosion-proof and protective properties, as well as corrosion resistance and aging resistance. It can operate reliably for long periods in indoor, outdoor, and various specialized industrial environments.

5.2.2 External structure

1. To meet the requirements for long-term stable operation and explosion-proof performance of the detector, Flame detector It uses a housing made of an aluminum die-cast structure. The housing is divided into a shell and a bottom cover.

2. To ensure explosion-proof performance, the housing and bottom cover are connected via a threaded joint, and a rubber sealing ring is installed on the mating surface. The cable entry holes and mounting hooks are both located on the housing for convenient wiring operations.

3. A plastic inner shell is used to secure and protect the circuit components. The front panel of the inner shell exposes only the UV flame sensor and indicator light, while the rear panel exposes only the terminal blocks, thereby preventing damage to the circuit during installation and wiring.

5.2.3 Technical Parameters

| Project |

Specification or Status |

|||

| Power supply |

Minimum |

Standard |

Maximum |

|

| 18VDC |

24VDC |

30VDC |

||

| Operating current |

≤ 45mA |

Preheating time |

After power-on 40 S |

|

| Perspective range |

Infrared 90 °, ultraviolet 120 ° |

Sensitivity Level |

Level I |

|

| Detection range |

>50 m ( 0.3m × 0.3m Gasoline fire) |

|||

| Response time |

≤ 20 S ( 0.3m × 0.3m Gasoline fire) |

|||

| Fire alarm |

When flames are detected in the monitored area, the detector enters... Alarm Status; Alarm Output relay actuated, red Alarm The indicator light is on; |

|||

| Alarm Threshold |

Multi-level adjustable (set via magnetic rod) Monitor The number of times the green light flashes each time indicates an alarm. Threshold |

|||

| Alarm delay |

0-30S Adjustable (set at the factory to 0S ) |

|||

| Drift compensation |

Intelligent Software Compensation Mode It can effectively compensate for drift caused by temperature changes, environmental variations, and long-term operation of components. |

|||

| Interference source suppression |

It can effectively suppress the interference from non-flame sources, such as sunlight (direct and reflected), common artificial light sources, and electric welding. | Wait |

|||

| Indicator light |

Monitoring status: Green light flashing Fire alarm status: Red light is constantly on. Fault status: Yellow light is constantly on. |

|||

| Explosion-proof rating |

And E xdIICT6Gb/ExtdA21 |

Protection rating |

IP 66 |

|

| Implementation standard |

G B 15631-2008 ,GB12791-2006 |

|||

Key words:

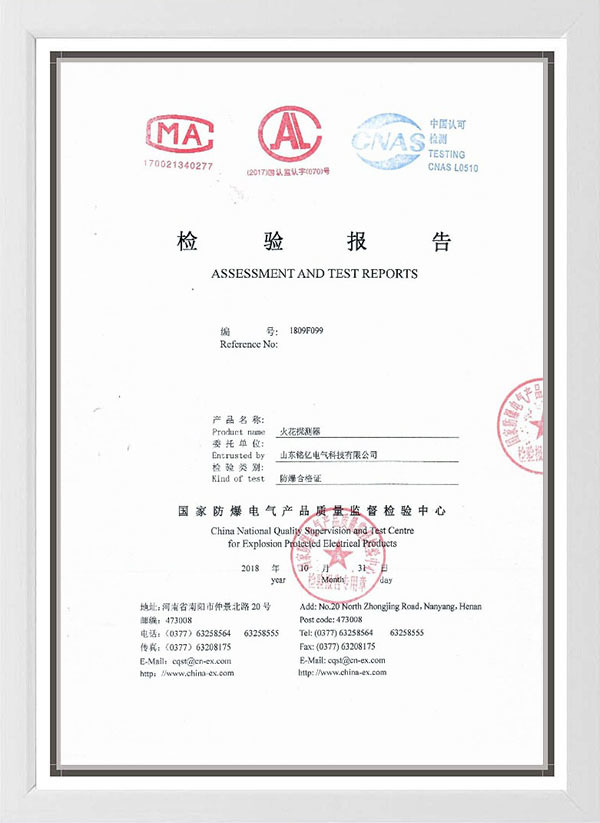

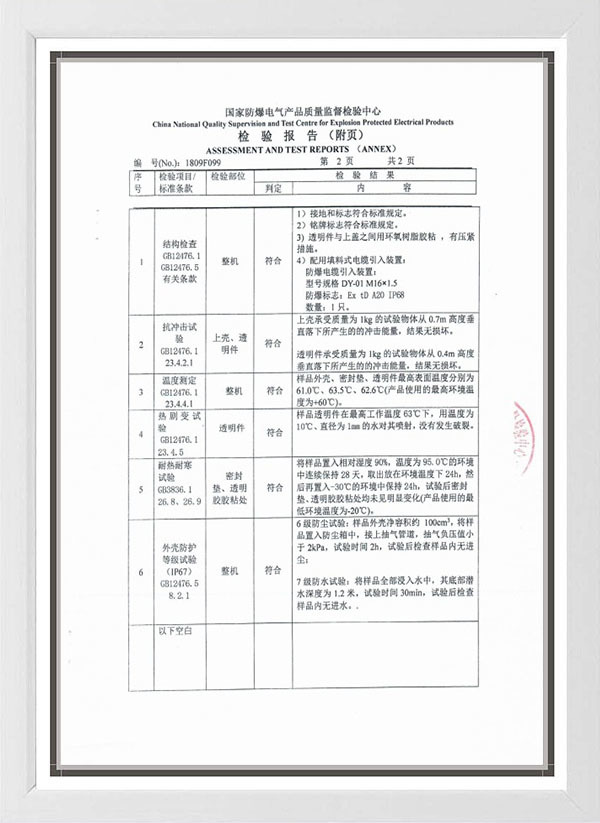

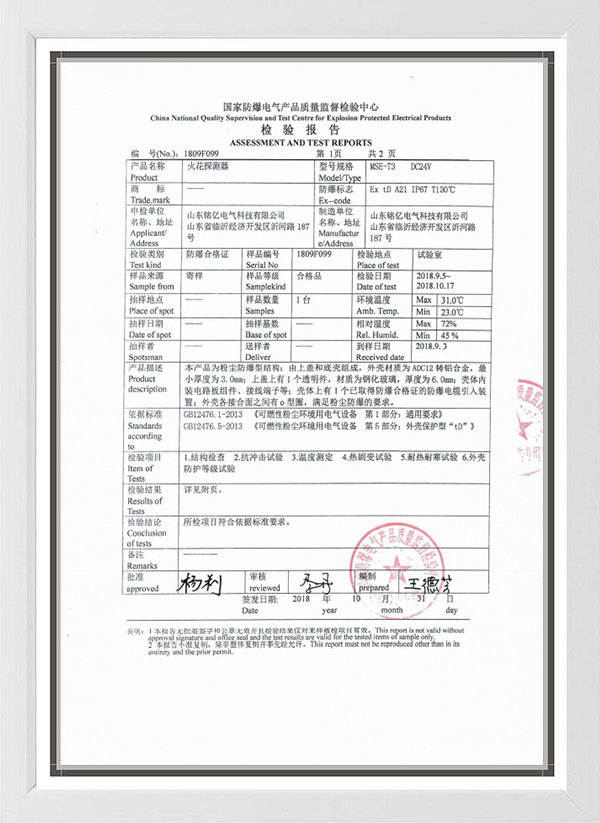

Spark detector inspection report

Spark detector inspection report

Spark detector inspection report

OUR SERVICE

Scientific research strength

Mingyi Technology relies on Linyi University to establish a research and development base for industry and academia, focusing on the research and development of industrial explosion-proof products. Strong technical strength and professional development team enable the product to meet the usage needs of different customers under different working conditions.

Quality Assurance

The independently developed and designed spark detection system has obtained multiple patents and software copyrights. The sensitivity and response time of the spark detection system can compete with well-known foreign brands. Has multiple independent invention patents. Passed 1SO9001 quality management system certification, explosion-proof certificate, inspection report, quality management system certification, and insurance.

Sales Service

We have dedicated after-sales service personnel to solve customers' problems one-on-one and provide them with usage skills to ensure the durability of the product in their hands.