PRODUCT

CONTACT US

Pangu Tiandi, Economic and Technological Development Zone, Linyi City, Shandong Province

MSE-S3 spark detector

Fire hazards in the processing industry: With the increasing environmental requirements for wood, metals, chemicals, boilers, etc., more and more dust or materials are transported and centrally processed through closed pipelines.

Classification:

Product Description

Dust removal pipeline spark detector:

Fire hazards in the processing industry: With the increasing environmental requirements for wood, metals, chemicals, boilers, etc., more and more dust or materials are transported and centrally processed through closed pipelines. This treatment method improves environmental quality and strengthens the process capability of centralized treatment, but at the same time, it also introduces new safety hazards. In such a pipeline transportation system, there is sufficient combustible raw materials and oxygen. During the production process, sparks are inevitably generated as a source of ignition. So, effective warning and elimination of large-scale fires or even explosions caused by ignition sources (sparks) becomes the key to controlling such fires.

Working principle: The pipeline spark detection and extinguishing system effectively captures the infrared radiation emitted by the ignition source (spark) in the pipeline through a spark probe installed on the conveying pipeline wall. At the corresponding distance (based on the conveying speed of dust or materials), an extinguishing device is installed to quickly start the high-pressure and high-flow atomization nozzle, extinguish the ignition source (spark) and issue an alarm notification. The specially designed high-pressure anti clogging nozzle has precise spraying angle and atomization effect, ensuring the coverage of water mist on the entire pipeline without the need for a large amount of water spraying. While extinguishing sparks, it will not affect your pipelines, dust removal, filters, and other equipment. At the same time, the uniquely designed high-pressure anti clogging nozzle has anti clogging characteristics, which can effectively prevent the clogging of the spray hole by water contaminated materials. The same extinguishing module can be used for extinguishing in other industries. In the metal processing industry, nitrogen or carbon dioxide can be used to extinguish sparks. After the spark ends, the system automatically stops extinguishing the operation. The entire process does not require manual intervention and operation, nor does it require interruption of your production operations, meeting your continuous production needs. At the same time, the system has linkage output points (passive normally open or normally closed contacts of relays), which are largely compatible with existing PLC and dust removal fan controllers for subsequent linkage measures.

Application field of dust removal spark detector: It can be applied in the following industries: wood industry, furniture industry, biomass industry, metal processing industry, food industry, feed industry, textile industry, tobacco industry, packaging industry, pharmaceutical industry, etc.

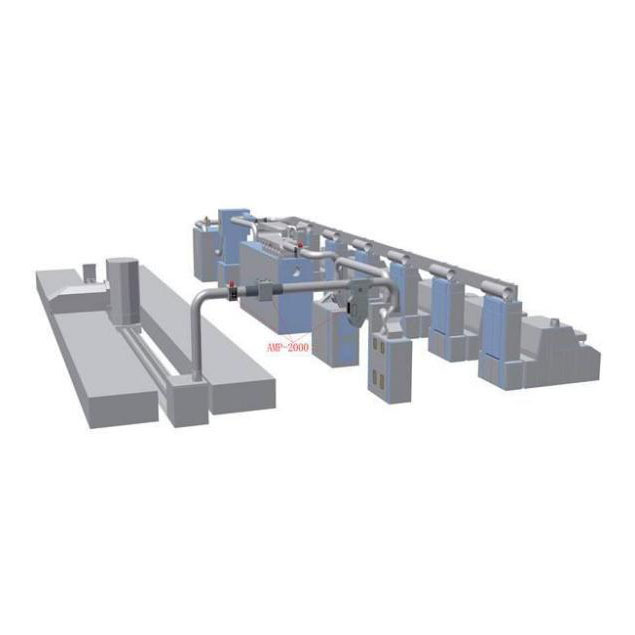

System composition: The pipeline spark detection and extinguishing system mainly consists of three parts: spark probe, control box, and extinguishing device.

Spark probe:

The spark probe is installed on the wall of the conveying pipeline, effectively capturing the infrared radiation emitted by sparks in the pipeline. Even if sparks are hidden in dense materials, the probe can sensitively detect them.

1. Sensitive detection.

2. Adopting photoelectric non-contact detection technology.

3. Wide angle detection design, which can fully cover the pipeline with only two probes.

4. The shell is sturdy and has an IP67 protection level.

5. Quick installation.

Control box:

1. Adopting advanced ARM chips, the spark response speed is fast.

2. The extinguishing operation will automatically terminate. Once the system cannot detect sparks, it will automatically stop extinguishing the operation; The production line can continue to operate without stopping or manual intervention, greatly improving production efficiency.

3. Detailed event records.

4. A complete and reliable self inspection system.

5. Configurable linkage measures.

6. Optional backup power module.

7. Each output point has a fuse to ensure there is no risk of short circuit.

Extinguishing device:

The extinguishing device is installed at a corresponding distance behind the probe. By quickly activating the solenoid valve, the high-pressure and high-flow atomizing nozzle is opened, and the atomized high-pressure water is injected into the pipeline, forming a low-temperature and oxygen free environment to extinguish the spark.

Alarm: Sparks found in the pipeline, on-site alarm, and ringing alarm.

Key words:

MSE-S3 spark detector

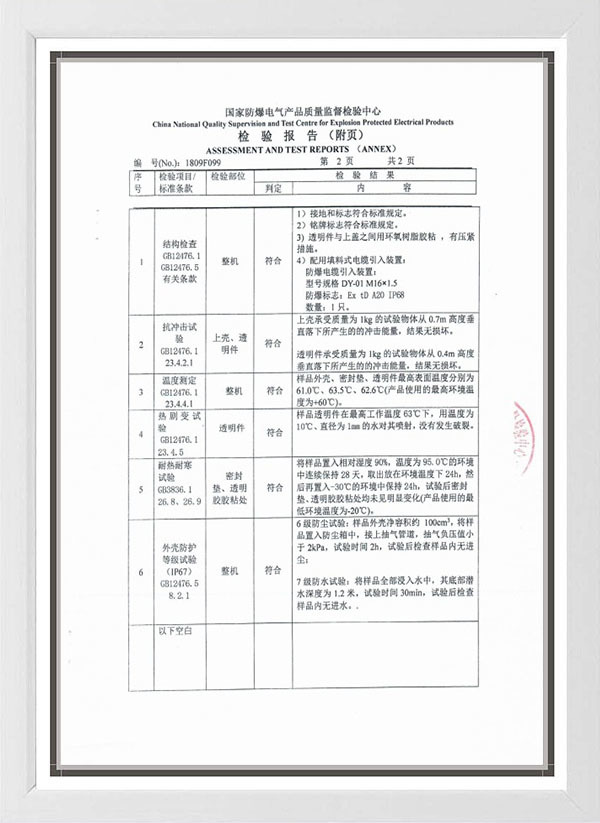

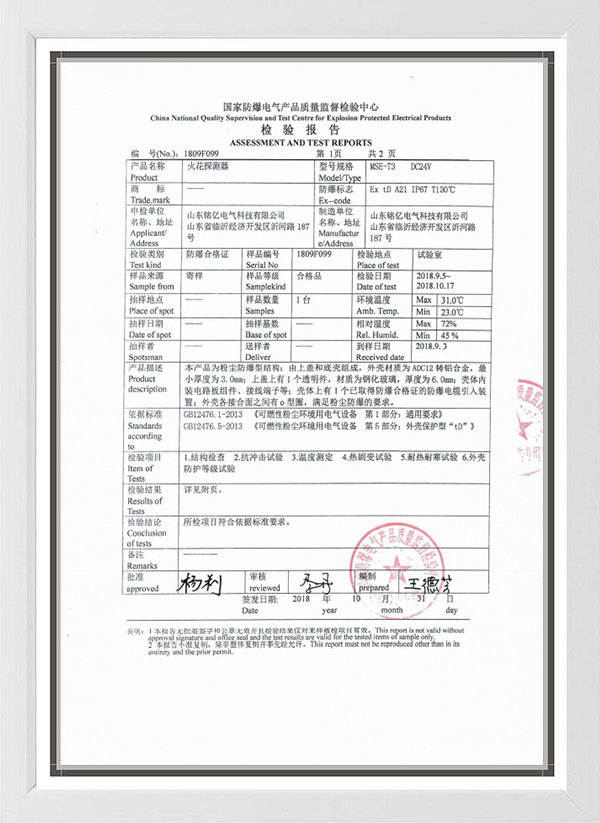

Spark detector inspection report

Spark detector inspection report

Spark detector inspection report

OUR SERVICE

Scientific research strength

Mingyi Technology relies on Linyi University to establish a research and development base for industry and academia, focusing on the research and development of industrial explosion-proof products. Strong technical strength and professional development team enable the product to meet the usage needs of different customers under different working conditions.

Quality Assurance

The independently developed and designed spark detection system has obtained multiple patents and software copyrights. The sensitivity and response time of the spark detection system can compete with well-known foreign brands. Has multiple independent invention patents. Passed 1SO9001 quality management system certification, explosion-proof certificate, inspection report, quality management system certification, and insurance.

Sales Service

We have dedicated after-sales service personnel to solve customers' problems one-on-one and provide them with usage skills to ensure the durability of the product in their hands.